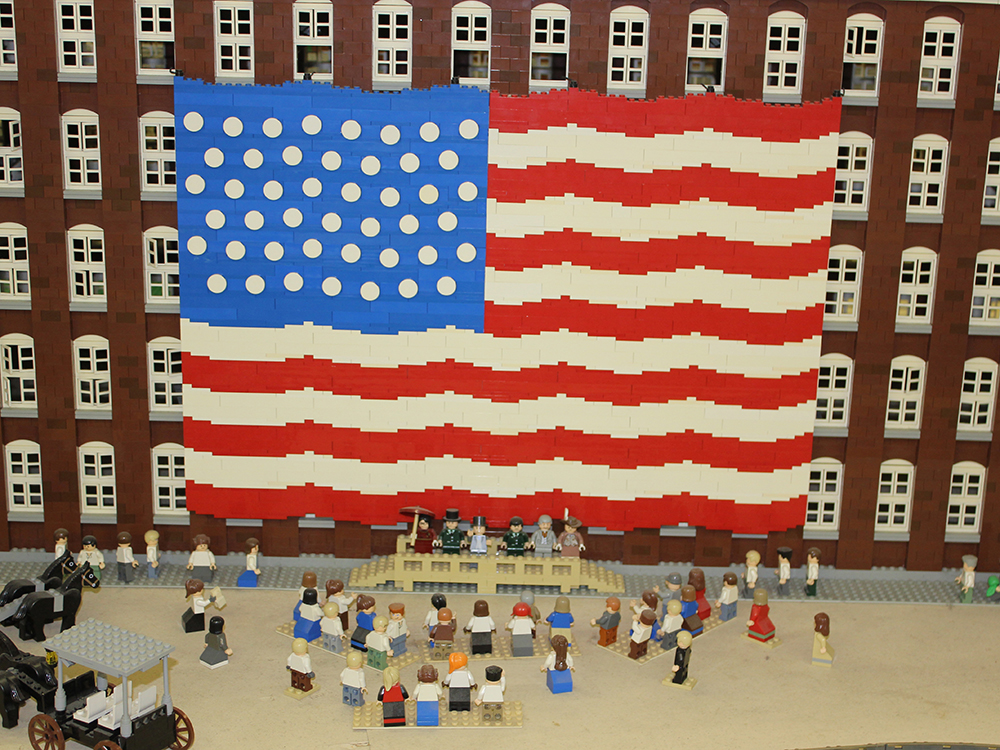

The LEGO® Millyard Project

The LEGO® Millyard is the largest permanent LEGO® installation at minifigure scale in the world, as recognized by Guinness World Records® here.

The installation at SEE represents Manchester’s Amoskeag Millyard as it might have looked circa 1900. The Amoskeag Manufacturing Company was commonly recognized as the largest textile manufacturer in the world by 1915. The Amoskeag mill complex spanned over a mile on the east side of the Merrimack River and half a mile on the west side. This model represents a portion of the east side, along with part of downtown Manchester, the city that the Amoskeag company helped to build.

This project marked the first time the LEGO® Company worked on a creative display of this scale with outside partners. These partners include: the SEE Science Center, FIRST (For Inspiration and Recognition of Science and Technology), CLD Consulting Engineers, and NELUG (the New England LEGO® Users Group). The City of Manchester also sponsored this project. The Manchester Historic Association provided research materials, and awarded SEE with an Historic Preservation Award for the project in 2006.

Here is a link to an article written about this amazing project:

“LEGO Millyard Spruce-Up” by Michael Ripley. ( From Issue 7 of BrickJournal, a magazine that spotlights the many aspects of the LEGO Community.)

Intro to LEGO® Millyard & Feature: Pine Island Park

This video introduces the LEGO® Millyard Project at the SEE Science Center, the largest permanent installation of LEGO® bricks at minifigure scale in the world.

The first featured closeup is Pine Island Park, which used electricity to power it’s rides. It includes a very special roller coaster built by LEGO® Master Builder, Jamie Berard, judge on the TV show LEGO Masters on Fox.

Did you know that Manchester, NH had electric street lights two weeks before the Edison’s Pearl Street Station began operations in New York?

Feature: Machines & Process at Amoskeag

This video is a brief overview of the types of machinery used at Amoskeag Manufacturing company to make cloth. And a closer look at the models built to illustrate the process.

Did you know that the SEE Science Center is in the same building as the Manchester Historic Association’s Millyard Museum? You can learn more about millyard history by visiting their website.

Have you ever built a model without instructions like the builders of our project did? Why not give it a try?

Feature: Details Downtown

This video features some of the more detailed buildings and intricate architecture in the LEGO® Millyard Project built by volunteers.

Do you like to experiment with creative building? Learn more about techniques creative builders use in this Brick tip by LEGO® Masters Fox Judges Jamie & Amy.

Share photos of your creations with us on Facebook, Instagram & Twitter.

Feature: Coal yard

Our LEGO® Millyard Project close up this week is the coal yard. Watch to the end for some inside information only a select number of builders know about the construction of the project.

Feature: Notre Dame Bridge

Take a closer look at the Notre Dame Bridge Model in the LEGO® Millyard. Learn now it was constructed with the volunteer who built it Teddy Welsh. Discover why it was included in project and helps explain why we no longer make textiles in Manchester’s millyard.

Try building a bridge for yourself. Here is an activity guide from PBS to get you started.

Feature: Union Train Station

In this close up of the model of the Union Train Station in the LEGO® Millyard Project, volunteer Joe Comeau explains how they had to reverse engineer the architecture of the ‘extinct’ building.